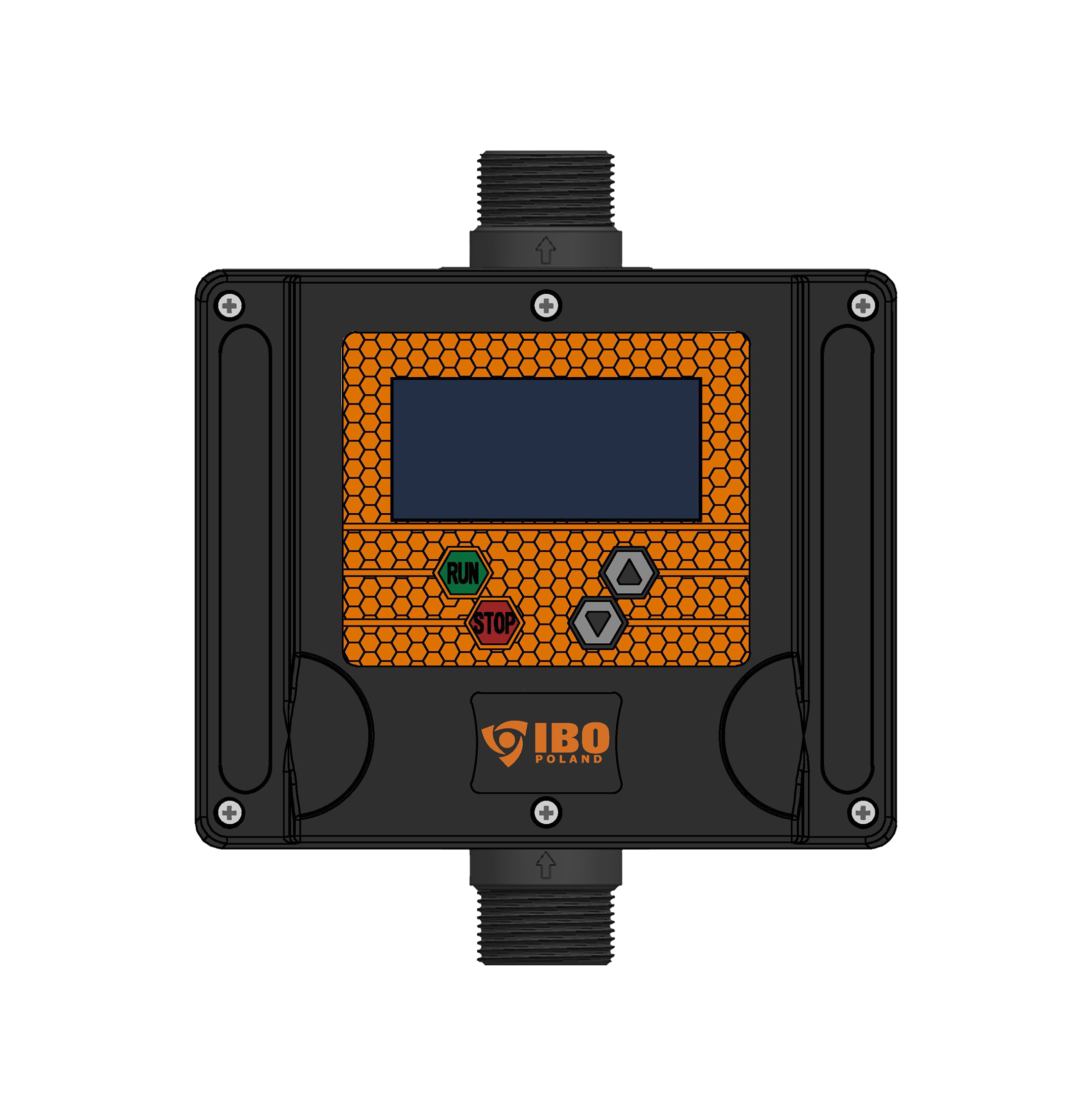

Description

Our intelligent pump controller IVR 03 is a control and protection device for direct connection of surface pumps, submersible pumps, etc. maintaining a constant, set water pressure by changing the speed of the pump engine. The IVR 03 inverter uses SPWM (sinusoidal module of pulse width) and a high -performance spatial vector using V/F VVF control (variable speed, variable frequency). By analyzing the pressure in real time, the inverter adjusts the pump speed to the current system's demand. The variable rotational speed of the pump stabilizes the pressure, which significantly saves water and electricity consumption.

The purpose of the device and assembly requirements

The IVR 03 is intended for work in water systems and must only be installed by people with appropriate technical qualifications. The manufacturer reserves that the device is not intended for use by end users without the participation of the installer. Due to the possibility of electromagnetic emissions, the manufacturer recommends the use of shielded cables, appropriate grounding and network filters in accordance with the requirements of the EN 61800-3 standard. The product is not a household device and is not intended for self -installation in such an environment. When used in the home environment, it is required:

- cable screening,

- use of input and output filters,

- compliance of the installation with the guidelines for the environment 1. (EN 61800-3).

The manufacturer is not responsible for interference resulting from an incorrect installation, not taking into account the above guidelines. The most important features that distinguish IVR 03 from popular ON/OFF control devices:

- Increasing energy efficiency. Compared to a traditional method, the water supply system with a constant pressure with a frequency converter saves energy by 30%-60%.

- Long -term pump reliability: average torque and abrasion on the shaft decreases due to the decrease in average speed, which ensures longer pump life. The Soft-Start function and stopping the device allows you to eliminate a hydraulic impact (sudden pressure increase accompanying a quick retention or starting liquid flow).

- Comprehensive protection: The system has the most versatile technology of hypertension, overvoltage, undercoat, short -circuit, blocking the rotors, the ability to protect the pump against dry -one without the need to install probes/sensors in the well.

- Advanced technology: PID algorithm control, technology addressed for pump drive control.

APPLICATION

Model IVR 03-030 S will work wherever there is a need to maintain constant water pressure in the installation and control and protection of the pump or set of two pumps.

Estimated typical use:

- supplying water from a well,

- irrigation of greenhouses, gardens, fields,

- collecting and using rainwater,

- water supply installations,

-

Industrial devices.

Industrial pattern No. RP. 27368

Parameters

- Power: 0.37-2.2 kW,

- Power supply: 3 ~ 400 V permissible fluctuations (300-450 V),

- Rated output voltage: 3 ~ 400 V,

- Rated output voltage of the second pump: 3 ~ 400 V / 50 Hz,

- Electricity: 7 A,

- Frequency at the entrance: 50/60 Hz,

- Exit frequency: 20-50/60 Hz,

- Pressure setting range: 0.5-9 bar,

- Installation of a pressure tank with a volume of not less than 2 l,

- Environmental temperature range: 0-40 ° C,

- Medium: pure water at a temperature of 0 to 100 ° C,

- The pressure required for automatic start: 0.3 bar lower than the set pressure but not lower than 0.5 bar,

- Electrical installation: absolutely effectively grounded,

Basic technical characteristics

- Control characteristics:

- Double flow control,

- Pressure control,

- Control method:

- Manual,

- Automatic,

- Flow control characteristics: Impulse of the test electrode and flow switch,

- Pressure control characteristics: 24 V, 4-20 MA pressure sensor.

Recommendations for the installation and operation of the inverter

To ensure the correct operation of the device and avoid interference at work, follow the following rules:

- The length of the cable between the inverter and the engine should not exceed 5 meters if no additional protection has been used.

- It is not recommended to use inverter with deep pumps, in which the power cord is usually much longer. In such cases, additional technical solutions are required, such as:

- output filters (sinusoidal or DV/DT),

- ferrite rings on the wires,

- shielded cable with correct grounding.

- The inverter should not be installed near devices particularly sensitive to electrical interference, such as PLC drivers, control panels, alarm systems.

Additional information

The device is intended for standard installations with a short section of the cable between the inverter and the engine.

Application in unusual installations, such as deep -sea pumps, systems with very long cables or Power supply from a network with unstable parameters, it can cause interference in the inverter's operation or lead to damage.

In such cases, an earlier consultation with a qualified installer is recommended. Installations not in accordance with the above recommendations may result in the inability to provide technical and service support.

- Lifting: M,

- Efficiency: l/min.,

- Suction capacity: M,

- Power: 2.2 kw,

- Power supply: ,

- Frequency: 50 Hz,

- Power consumption: 12.0 AND,

- Engine speed: rpm ,

- Dimensions: 210x167 mm

- Libra: kg,

Our intelligent pump controller IVR 03 is a control and protection device for direct connection of surface pumps, submersible pumps, etc. maintaining a constant, set water pressure by changing the speed of the pump engine. The IVR 03 inverter uses SPWM (sinusoidal module of pulse width) and a high -performance spatial vector using V/F VVF control (variable speed, variable frequency). By analyzing the pressure in real time, the inverter adjusts the pump speed to the current system's demand. The variable rotational speed of the pump stabilizes the pressure, which significantly saves water and electricity consumption.

The purpose of the device and assembly requirements

The IVR 03 is intended for work in water systems and must only be installed by people with appropriate technical qualifications. The manufacturer reserves that the device is not intended for use by end users without the participation of the installer. Due to the possibility of electromagnetic emissions, the manufacturer recommends the use of shielded cables, appropriate grounding and network filters in accordance with the requirements of the EN 61800-3 standard. The product is not a household device and is not intended for self -installation in such an environment. When used in the home environment, it is required:

- cable screening,

- use of input and output filters,

- compliance of the installation with the guidelines for the environment 1. (EN 61800-3).

The manufacturer is not responsible for interference resulting from an incorrect installation, not taking into account the above guidelines. The most important features that distinguish IVR 03 from popular ON/OFF control devices:

- Increasing energy efficiency. Compared to a traditional method, the water supply system with a constant pressure with a frequency converter saves energy by 30%-60%.

- Long -term pump reliability: average torque and abrasion on the shaft decreases due to the decrease in average speed, which ensures longer pump life. The Soft-Start function and stopping the device allows you to eliminate a hydraulic impact (sudden pressure increase accompanying a quick retention or starting liquid flow).

- Comprehensive protection: The system has the most versatile technology of hypertension, overvoltage, undercoat, short -circuit, blocking the rotors, the ability to protect the pump against dry -one without the need to install probes/sensors in the well.

- Advanced technology: PID algorithm control, technology addressed for pump drive control.

APPLICATION

Model IVR 03-030 S will work wherever there is a need to maintain constant water pressure in the installation and control and protection of the pump or set of two pumps.

Estimated typical use:

- supplying water from a well,

- irrigation of greenhouses, gardens, fields,

- collecting and using rainwater,

- water supply installations,

-

Industrial devices.

Industrial pattern No. RP. 27368

Parameters

- Power: 0.37-2.2 kW,

- Power supply: 3 ~ 400 V permissible fluctuations (300-450 V),

- Rated output voltage: 3 ~ 400 V,

- Rated output voltage of the second pump: 3 ~ 400 V / 50 Hz,

- Electricity: 7 A,

- Frequency at the entrance: 50/60 Hz,

- Exit frequency: 20-50/60 Hz,

- Pressure setting range: 0.5-9 bar,

- Installation of a pressure tank with a volume of not less than 2 l,

- Environmental temperature range: 0-40 ° C,

- Medium: pure water at a temperature of 0 to 100 ° C,

- The pressure required for automatic start: 0.3 bar lower than the set pressure but not lower than 0.5 bar,

- Electrical installation: absolutely effectively grounded,

Basic technical characteristics

- Control characteristics:

- Double flow control,

- Pressure control,

- Control method:

- Manual,

- Automatic,

- Flow control characteristics: Impulse of the test electrode and flow switch,

- Pressure control characteristics: 24 V, 4-20 MA pressure sensor.

Recommendations for the installation and operation of the inverter

To ensure the correct operation of the device and avoid interference at work, follow the following rules:

- The length of the cable between the inverter and the engine should not exceed 5 meters if no additional protection has been used.

- It is not recommended to use inverter with deep pumps, in which the power cord is usually much longer. In such cases, additional technical solutions are required, such as:

- output filters (sinusoidal or DV/DT),

- ferrite rings on the wires,

- shielded cable with correct grounding.

- The inverter should not be installed near devices particularly sensitive to electrical interference, such as PLC drivers, control panels, alarm systems.

Additional information

The device is intended for standard installations with a short section of the cable between the inverter and the engine.

Application in unusual installations, such as deep -sea pumps, systems with very long cables or Power supply from a network with unstable parameters, it can cause interference in the inverter's operation or lead to damage.

In such cases, an earlier consultation with a qualified installer is recommended. Installations not in accordance with the above recommendations may result in the inability to provide technical and service support.