The A 2-Poto series is used to pump clear liquids and raw sewage. A single -channel rotor with high parameters means that this type is perfect for sewage treatment plants, industrial sewage system, agriculture and dehydration.

Characteristic

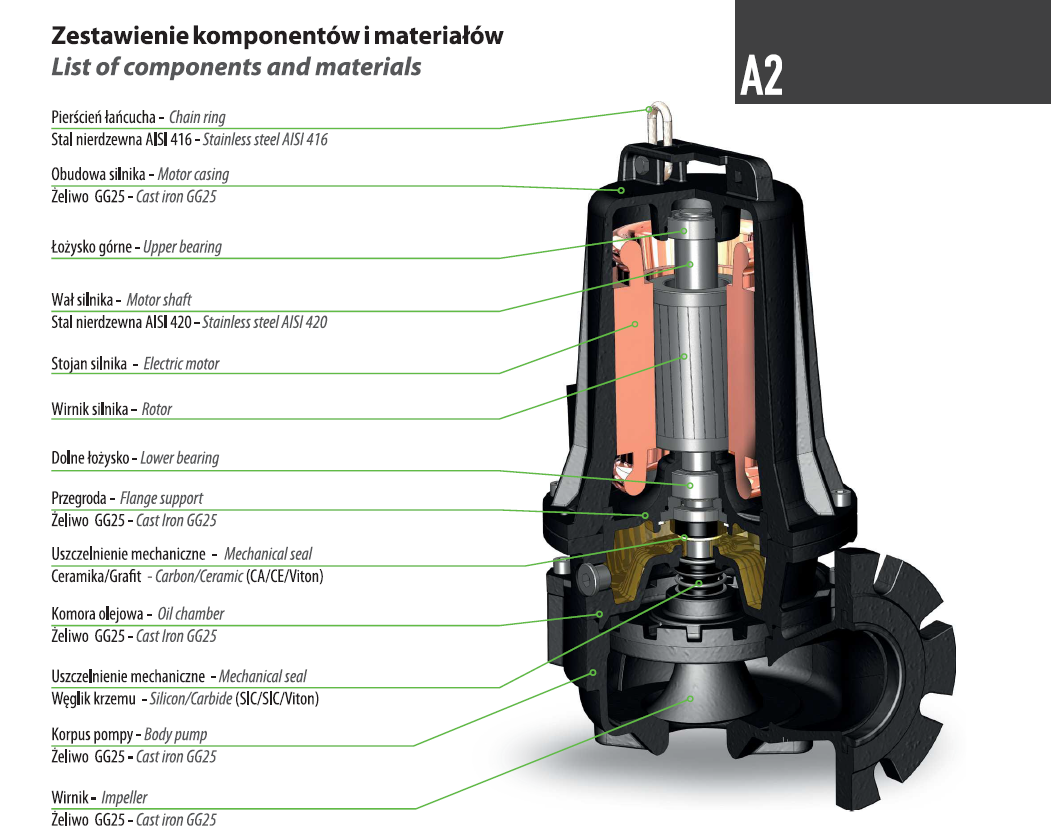

All main elements are made of gg25 cast iron. Two separate mechanical seals (engine page in the oil chamber, the rotor page in contact with liquid) and high quality parts ensure excellent operation and reliability of the product.

Advantages of A2 pumps

The A2 series pumps have a single -channel rotor closed with excellent raw sewage pressing properties. We only have one channel that limits us the chapter of the stream in the hydraulic system of the pump, which means that the fibrous fractions are not able to wind on the rotor. At the same time, the rotor efficiency is much higher than in the case of pumps with a free flight and Vortex rotor.

Installation of A2 pumps

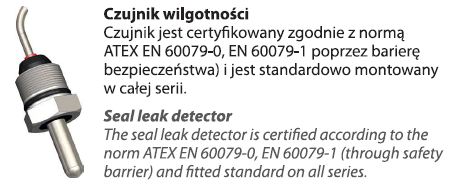

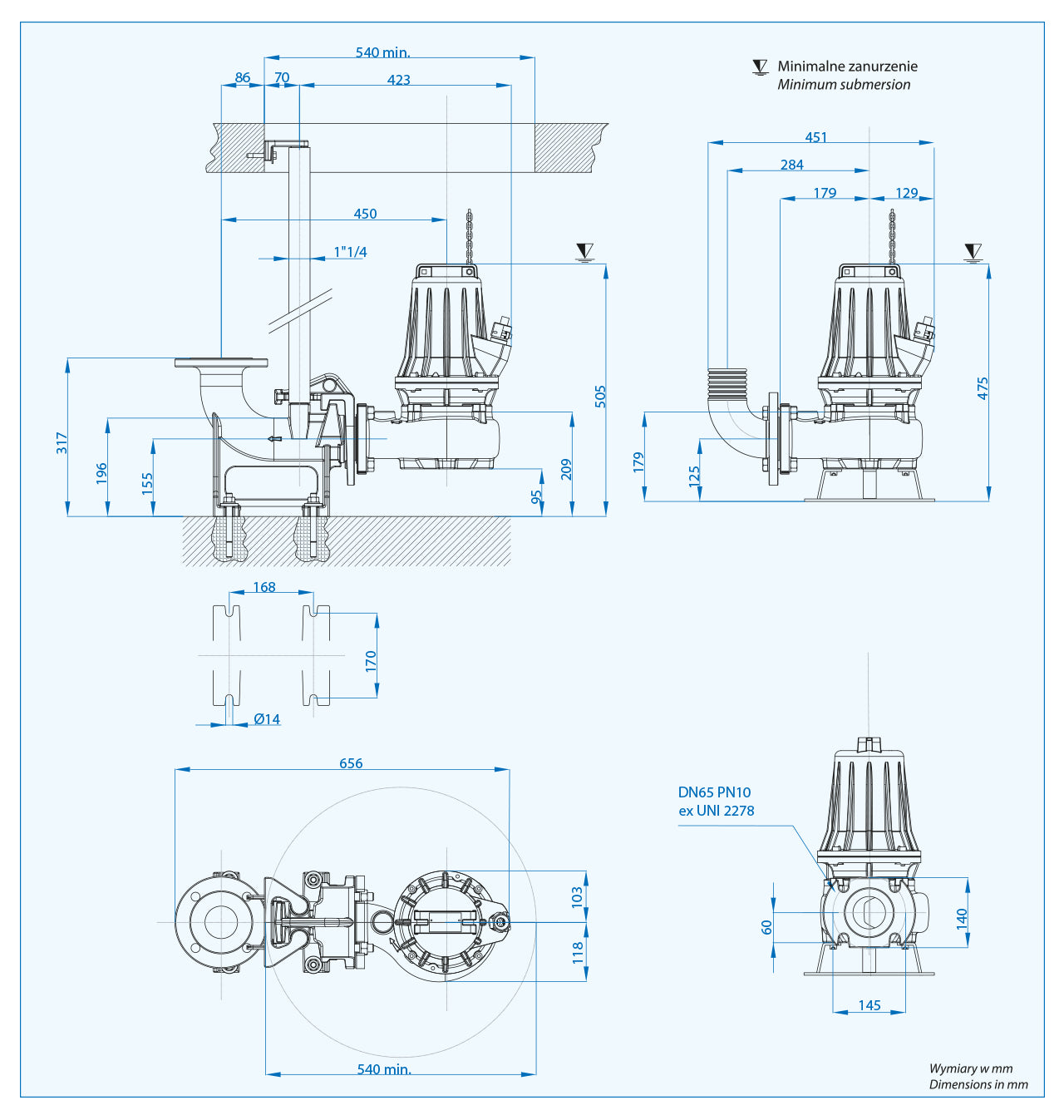

Due to the fact that A2 series pumps are intended for professional applications in most cases are installed on coupling feet DRENO type: AND, B or Long in municipal and industrial pumping stations. For their control, we offer customers advanced control systems with appropriate engine protection and protection against pump damage, such as two independent humidity probes in the engine chamber and the oil chamber, e.g. CR3.1.

We recommend that the selection of pumps with a single -channel rotor is open consulted with our specialists to confirm the expected parameters of the pumping station.

Characteristics

- Single -channel rotor closed with a 40 mm flight,

- LEVEL FROM THE SONDENCE PUMP ended with a dn65 PN10 collar,

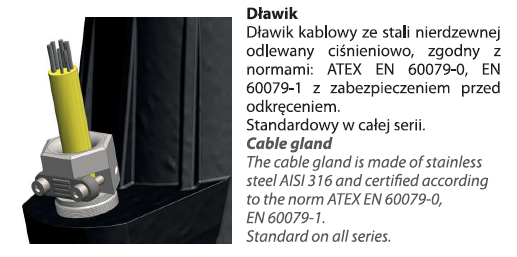

- 10 m supplying cable ended with free clamps,

- T1-T2 thermal protection built into the engine winding connected to the external control panel,

- Warranty and post -warranty service,

- 24 months warranty.